Planning on adding epoxy to your garage floor? Find out how best to prep the area first.

A garage floor can take quite a beating over the years, with everything from heavy foot traffic and spills to dirty vehicle tires and chemicals.

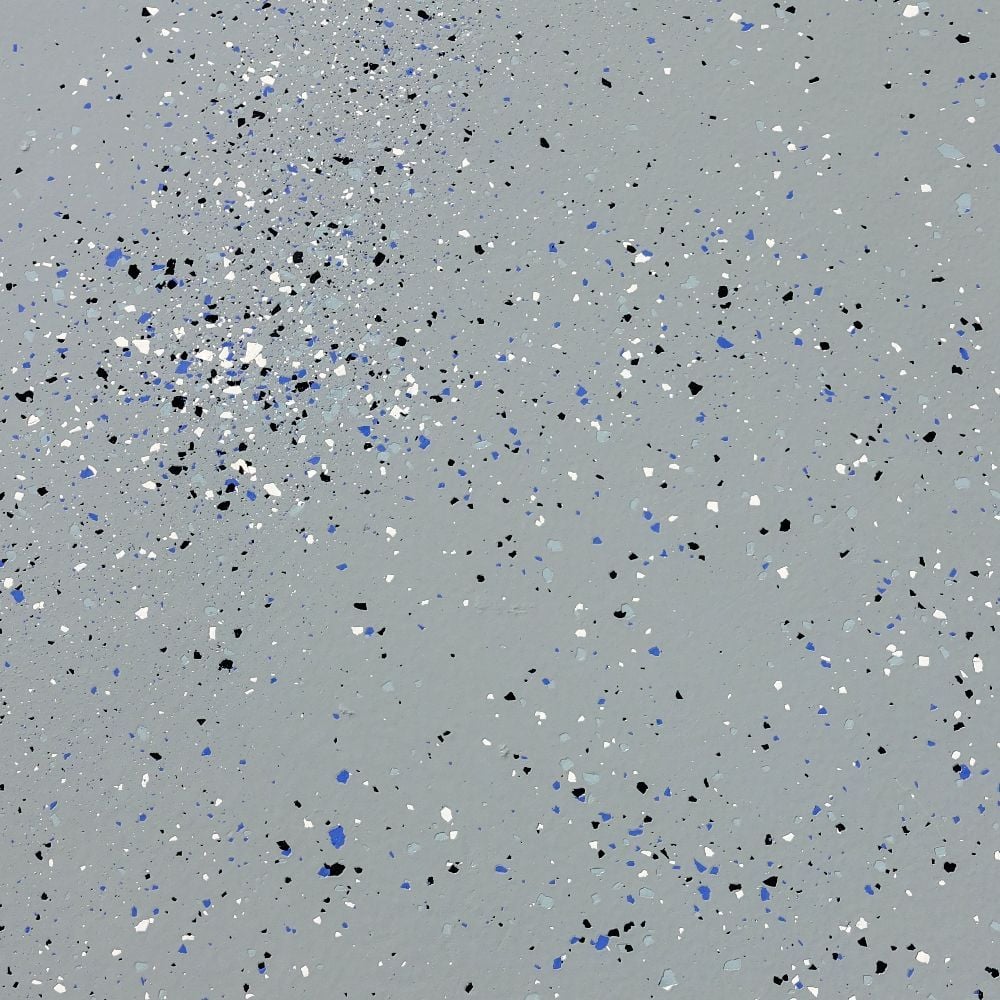

If you want to protect your garage floor and improve its appearance at the same time, applying an epoxy coating is a great option. Adding epoxy to garage floors provides a durable, stain-resistant surface that is easy to clean and looks great.

However, before you can apply epoxy to your garage floor and enjoy the final result, you need to properly prepare the surface.

In this article, we’ll walk you through the necessary steps to take in order to prep your garage floor for a long-lasting epoxy coating.

Step 1: Remove Everything From the Garage Floor

To get started on prepping your garage floor for epoxy, you’ll first need to empty the entire area. While things hanging on the walls can stay, it’s important that nothing on the floor gets left behind.

This includes any tools, vehicles, workbenches, cabinets, or anything else that sits on the floor. You want to start with a blank canvas for the next steps in the prep process.

Keep in mind that you’ll want to have access to wherever you want to apply the epoxy, so be sure to remove freestanding cabinets, furniture, or storage shelves that touch the floor.

Step 2: Lift Any Sinking Concrete

Once you get all of your things off the floor and out of the garage, you’ll be able to see more of what you’re working with.

If it’s been a long time since you were able to see your garage completely cleared out, you might notice that the concrete floor has begun to sink, or maybe the floor has settled more than before.

If you see that some areas of your garage floors look settled, sunken, or that are falling away from the wall, you will need to lift the area with concrete leveling before applying epoxy to the surface.

Getting your garage floor leveled and back to its original position before applying the epoxy makes sure that when you apply the coating, you don’t have to go back and redo it later in order to lift and repair the sinking areas of concrete.

Step 3: Clean the Garage Floor Thoroughly

Once you’ve made sure that your garage floor is level and clear of any belongings or furniture, you’re ready to get to work on deep cleaning it.

In order for the epoxy to stick, the concrete must be free of any chemicals, oil, dirt, and debris. So, start by sweeping the floor and removing any built-up dust or dirt. Then, you can treat any stains and oil spots with degreasing agents or other specialized cleaning products.

After the stains are removed, you can clean the floor with an old mop or a thick-bristled push broom and a soap and water mixture. Make sure you rinse thoroughly and let the concrete dry completely.

If you’ve gotten your concrete professionally leveled in preparation for applying epoxy, they will likely have cleaned and rinsed off the surface of your garage as part of their cleanup process, but it’s good to clean the concrete and rinse again to make sure that the cleaning agents, dust, and soap get washed away.

Step 4: Protect the Walls

When your concrete is clean and dry, you’re almost ready for the most important step in the process.

But before you can move on to roughing up the surface of the concrete, you need to first protect the walls and any areas that you don’t want to get covered in dust if you plan on grinding.

To do this, you can use simply use tape and plastic sheets to cover walls, windows, shelving, and any decorative items you have hanging.

Step 5: Rough Up the Concrete Surface

In addition to being free of dirt, oil, and other debris, the surface of your garage must also be rough rather than smooth so that the epoxy can bond to it.

There are different ways to go about doing this, but the most common methods for achieving this goal are grinding down the surface or applying an acid etching solution.

Concrete Grinding

To grind the surface of your concrete, you’ll need a hand grinder with a plate suitable for sanding down concrete. Go in circles around the entire surface of the garage floor, making sure to keep the grinder level and avoid gauging or digging any divots into the concrete.

The goal here is to create a rough surface and open up the pores of the concrete so the epoxy can stick, but you don’t want to create any large variance in the surface of the floor.

Make sure to grind away any paint or stuck-on materials, and try your best to get every corner and crevice where you plan to apply the epoxy.

When using a hand grinder, you’ll likely need knee pads or some sort of cushioning as this process can take a few hours depending on the size of your garage. Also, be sure to wear the proper safety equipment, like a dust mask and goggles, to protect yourself from the concrete dust while grinding.

Once you’re finished grinding the concrete, you can remove the plastic coverings around the garage, sweep or vacuum up as much dust as possible, then rinse the surface of the concrete in an effort to remove any remaining concrete dust.

Acid Etching

If you’re not comfortable with using a concrete grinder to add texture to your garage floor, you can also use an acid etching product to get similar results. However, this method is controversial among concrete professionals as it is a little more complicated to perform, can lead to inconsistent results, and comes with health hazards.

It’s also important to note that if there are any paint, glue, oil, or other spots, the acid will not be able to etch the concrete and will instead sit on top of those stains, so make sure to take care of them before starting the etching process.

To apply the product, spread it out across the entire garage floor, then work it into the surface with a thick-bristled brush. Let it sit for the recommended amount of time, which will vary depending on the product you use.

When the appropriate amount of time has passed, you’ll have to neutralize the etching acid, then rinse off the floor thoroughly to ensure there is no acidic residue left in the concrete, which can affect how well the epoxy bonds to your concrete.

You may have to repeat the acid etching process again if your garage floor is not rough enough to the touch.

If you plan to attempt acid etching on your concrete, we recommend following along closely with the instructions provided with the product you’re using and finding additional in-depth tutorials on acid etching as it is a complicated and potentially dangerous process.

Step 6: Fill Any Cracks in the Slab

After your concrete is roughed up, you’re one step closer to having a smooth, durable epoxy finish. But before you can get started applying the coating, you’ll need to fill any cracks or gaps in your garage floor.

To do this, you can purchase and apply an epoxy concrete crack filler or repair product. Follow the specific instructions, as they vary from product to product.

Step 7: Rinse the Concrete and Let Dry Thoroughly

The final step in preparing your garage floor for epoxy is simple. You’ll want to do another quick pass with the hose to make sure there is no remaining dust or debris.

After that, you’ll have to leave the garage floor to dry out completely. Applying epoxy to a floor that’s still wet could result in a poor bond, leaving you with cracking, peeling, or bubbling.

Your Next Steps for an Epoxied Garage Floor

Prepping for a garage floor epoxy coating may seem like a complicated undertaking, but it's well worth the effort. A properly prepped surface will ensure that the coating adheres well, leading to a beautiful, long-lasting finish that will protect your garage floor for years to come.

If you happen to have uneven, sinking garage floors that need taking care of before advancing on to the next steps in the preparation process, A-1 Concrete Leveling can help.

Here at A-1, we’ve been lifting and leveling settled concrete, including garage floors, for over 30 years. We also provide quick and easy crack repair services that can get you right where you need to be in your garage epoxy project or other concrete repair needs.

Click the link below to request a free onsite cost estimate with one of the A-1 Concrete experts!

Want to know more? Check out these related resources from Concrete Academy:

Sarah Etler joined A-1 Concrete Leveling after receiving her Bachelor of Arts degree in English from Northern Kentucky University. As A-1's Content Marketing Manager, she works closely with industry experts to produce content that will best answer questions related to concrete repair and maintenance practices. Sarah loves living a life full of discovery and is excited every day to see what new things she can learn and share with those around her.